All Products

-

Juan Guevaramuy buen trato con el vendedor y muy buena asesoria y el producto está trabajando muy bien ya tiene un año y no he tenido ningún problema

Juan Guevaramuy buen trato con el vendedor y muy buena asesoria y el producto está trabajando muy bien ya tiene un año y no he tenido ningún problema -

Obert MatetakufaI'm very happy with the business deal and all the support they are giving . A very good business partner

Obert MatetakufaI'm very happy with the business deal and all the support they are giving . A very good business partner

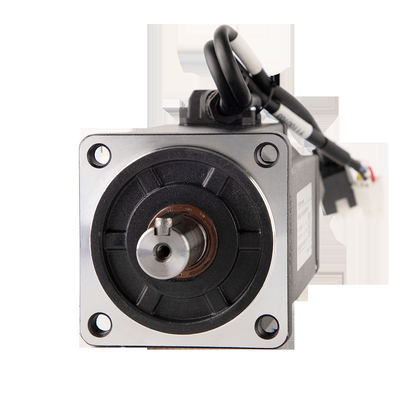

220V 750W AC Servo Motor Single Lap 17bit Feedback Element 2.4NM Rated Torque

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Rated Voltage | 220 V | Rated Power | 750 W |

|---|---|---|---|

| Rated Torque | 2.4 N.m | Peak Torque | 7.2 N.m |

| Rated Current | 4.8±10% AMS | Peak Current | 14.4±10% AMS |

| Rated Speed | 3000 RPM | Maximum Speed | 5000 RPM |

| Highlight | 750W AC Servo Motor,2.4NM AC Servo Motor,Single Lap AC Servo Motor |

||

Product Description

220V 750W AC Servo Motor Single Lap 17bit Feedback Element 2.4N.M Rated Torque

Servo motor refers to the engine that controls the operation of mechanical components in the servo system. It is an indirect speed change device of auxiliary motor. The servo motor can control the speed, and the position accuracy is very accurate. It can convert the voltage signal into torque and speed to drive the control object. The rotor speed of the servo motor is controlled by the input signal and can respond quickly. In the automatic control system, it is used as the actuator, and has the characteristics of small electromechanical time constant and high linearity. It can convert the received electrical signal into the angular displacement or angular speed output on the motor shaft. Its main feature is that when the signal voltage is zero, there is no rotation phenomenon, and the speed decreases uniformly with the increase of torque.

![]()

Parameter:

![]()

Installation notes

1. When the installation/removal part is at the end of the motor shaft, please do not knock

the shaft hard to prevent the encoder at the other end of the shaft from being damaged.

2. Try to prevent the shaft seat from vibrating to prevent damage to the bearing.

Recommended Products